Customer Success

Customer Success: Costa Rica Wind Turbine

Crowley successfully shipped six oversized, overweight Canadian wind turbine blades from Port Everglades, Fla., to Limon, Costa Rica. Crowley transported the blades quickly and safely on board the Lift-on/Lift-off (Lo/Lo) vessel Stadt Emden, an often overlooked solution for break-bulk shipments. The decision to move this cargo via a Lo/Lo vessel instead of a traditional Roll-on/Roll-off (Ro/Ro) ship meant a faster delivery by more than a week – a time savings that allowed Crowley to meet the tight deadline required by the shipper. The Challenge Each of the six blades weighed more than two-and-a-half tons and measured just over 72 feet…

Customer Success: Peregrino Oil Field in Brazil

In late 2009 and early 2010, Crowley had the opportunity to transport oversized offshore equipment and drilling packages to Peregrino oil field in Brazil, located more than 50 miles offshore east of Rio de Janeiro. The production platform, jackets, and packages were loaded on six barges in Ingleside, Texas, and were transited over a period of 35 days, including one scheduled fuel stop in Trinidad. When the project was complete in February 2010, all Crowley tugs and barges returned to the Gulf of Mexico after nearly five months at work – making the project one of the largest Crowley operations…

Customer Success: Orlan Tow Project

On three separate occasions, Crowley successfully towed Orlan, a 312-foot concrete island drilling structure (CIDS), for drilling projects in Russia. The Orlan has a 34-foot draft and consists of four basic components – a steel mud base, a concrete brick caisson, and two steel deck barges on which the drilling rig, support equipment, and quarters are mounted. Pulled by two Crowley Sea Victory class 7200 BHP, twin-screw, oceangoing tugs, and a third arctic-ice management tug, the first tow in 2001 moved Orlan from its stack site near Northstar Island, off Prudhoe Bay, Alaska, to Sovetskaya Gavan, Russian Federation. This relocation…

Customer Success: Alaska Sealift DOYON

In 2010, Crowley’s high-deck-strength series deck barges, 455-8 and 455-7, delivered a DOYON drill rig to Prudhoe Bay, Alaska, to support BP’s North Slope drilling operations. The rig, which is capable of working efficiently in extreme arctic conditions, was originally loaded on the sister barges in the Columbia River in Vancouver, Washington, and were towed to the site by tugs Gladiator and Guardsman. 455-7 carried eight pieces of the drilling complex, consisting of 32 rig mats and totaling more than 4.3 million pounds, while 455-8 carried four pieces, consisting of 30 rig mats and totaling more than 3.6 million pounds. The Challenge The Crowley team faced several challenges during the…

Customer Success: Haiti Earthquake Relief

In the aftermath of the massive Haitian earthquake in January 2010, clearing debris out of the devastated Port-au-Prince Harbor was just the beginning. There were still millions of people living without food, water or shelter. The need for relief supplies wasn’t something that could be measured in days — each hour the situation was becoming more desperate. We instantly recognized the vital role we could play here and what needed to be done to help alleviate the suffering. The Challenge With the harbor virtually impassable to ships and all offloading facilities completely destroyed, getting relief supplies directly into the city…

Customer Success: Angola Beach Landing

Crowley safely completed the transport of oversized modules and support accessories from Houston, Texas, to the Cabinda Gas Plant, a destination located nearly three miles inland in the Cabinda Province of Angola, West Africa. The sealift’s four-vessel fleet included large (400-foot by 100-foot) barges paired with powerful ocean-going tugs, small lighter tugs to assist in the beaching operation and a myriad of support equipment. Though a challenging project, the supersized cargo was delivered successfully and without incident. The Challenge The crew aboard the four tug-and-barge sets carefully planned and navigated the 6,600-mile transit carrying the oversized cargo from Houston to…

Customer Success: USAID

During the late summer and early fall, Crowley’s Carlos Rice keeps one eye glued to the TV and the other on the phone. With hurricane season usually in full swing, he and his team are frequently called on to collaborate with USAID to assemble and often deliver life-saving supplies to islands throughout the Caribbean, usually with only a few hours advance notice. In August of 2007, when Hurricane Dean battered Jamaica with 150 mph winds that left a swath of destruction, we were ready to answer the call. The Challenge Delivering tens of thousands of relief supplies by air is…

Customer Success: Alaska Sealift 2010 – Eni

Two of Crowley’s high-deck strength barges, 455-3 and Marty J, towed by tugs Warrior and Commander, transported processing and utility modules, and other smaller structural components more than 8,000 miles from Gulf Island Fabricators in Houma, Louisiana, to Point Oliktok in Kuparuk, Alaska. The modules and components, each weighing nearly 4,000 tons, will support Eni’s development of the Nikaitchuq oil field. The oil recovered from the field will be the first from the North Slope not processed by facilities owned by BP or Conoco Philips. The Challenge The Crowley team needed to move 8,000 tons of cargo more than 8,000 miles on high-deck-strength barges, transiting the…

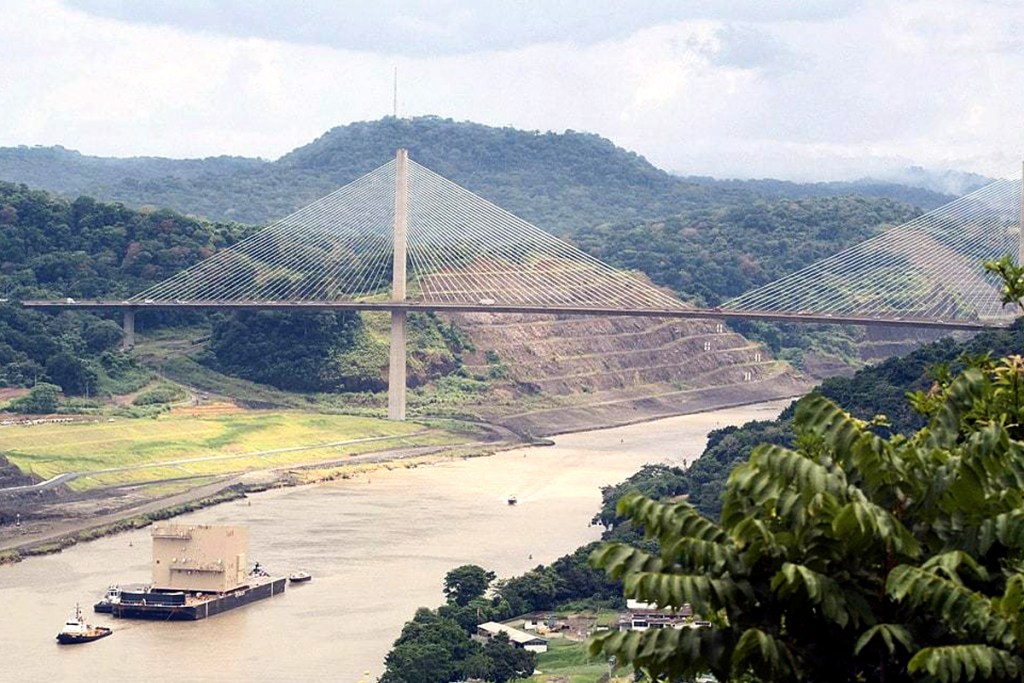

Customer Success: USS Iowa Tow

Set to become an interactive naval museum, the retired USS Iowa, which was a fully operational battleship through World War II, the Korean War and the 1980s, required relocation from San Francisco to its new home in the Port of Los Angeles. The ship’s custodian, the Pacific Battleship Center, engaged Crowley for the job (a video of the project can be viewed here). The decision was natural: Crowley had already towed the USS Iowa from Rhode Island through the Panama Canal to Suisun Bay (near San Francisco), as well as sister retired battleships, the New Jersey and Missouri, which were also converted to museums. Crowley…

Customer Success: BP Northstar Sealift

Crowley delivered BP’s Northstar Operations Center, which was made up of two pieces and weighed more than 3,511 tons, from McDermott Shipyards in Amelia, La., to Northstar Island in Alaska. The sealift required modifying the barge 455-3 to carry the cargo through the Panama Canal before transiting up the West Coast to Alaska, where Northstar Island, surrounded by deep water, presented a whole new set of challenges. The Challenge Crowley’s solutions team had to overcome major obstacles before the project began, as the project was about to go underway and at the delivery of the modules. The journey required transit…

Customer Success: Fresh Flower Warehousing, Order Fulfillment

In advance of Valentine’s Day 2014, CrowleyFresh fulfilled over 17,000 custom floral orders – amounting to 100,000 boxes of fresh flowers from Colombia and Equador — for a major supplier serving customers across the United States. This marked the third year that cold-chain warehouse and logistics services were jointly offered by the company to the flower industry in advance of one of the biggest holidays. The team prepared similarly for Easter and Mother’s day, which brought in influxes of rose and carnation orders. The Challenge In addition to supplying major flower suppliers with over 17,000 custom floral orders for individual…

Customer Success: Raising The Costa Concordia

Described as the largest, most technically demanding wreck removal operation ever attempted on a ship of its size, the wrecked Costa Concordia cruise liner was successfully removed from the Italian shoreline in July 2014. After the wreck, vessel owners, alongside others on a review board, began evaluating proposed salvage plans from more than 10 of the most experienced wreck removal and maritime salvage companies from around the world. After an exhaustive search, they selected Italian offshore service provider Micoperi and Crowley Maritime’s internationally-based TITAN Salvage. TITAN Salvage and Micoperi began the process of refloating the Costa Concordia, which was safely moored at…

Customer Success: Ocean Rangers

Of the 1.5 million tourists that visit Alaska annually, 60 percent make the trek on board the 27 cruise liners scheduled for the state’s ports. With an influx of so many ships and people each season, Alaska voters passed a ballot measure in 2006 that outlined regulations that protected the state’s wildlife and waterways from pollution, assessed appropriate taxes on the tourist industry and safeguarded local businesses. The resulting legislative change required the State of Alaska’s Department of Environmental Conservation (ADEC) to develop a program for enforcing these new measures, which were the first of their kind in any U.S.…

Customer Success: ATB and the Oil Pollution Act of 1990

As part of the Oil Pollution Act of 1990, older, single-hulled petroleum transport vessels have been gradually phased out in favor of double-hulled vessels that reduce the risk of environmental disasters. As part of our constant push for product innovation, we developed and have been continually refining our Articulated Tug Barge (ATB) design, working to create a vessel that facilitates safer more cost-efficient operations while mitigating environmental risks. Read more about the value of having Crowley’s construction managers as your advocate in the shipyard in the Crowley Connections article Eyes on Quality. Watch a short video outlining our Safe and…

Customer Success: American Petroleum Tankers

Today’s challenging economic climate has only reinforced the need for businesses, including shipping companies, to operate at maximum efficiency, while maintaining a commitment to safety and environmental awareness. Faced with this new financial reality, many ship owners have decided to divest themselves from the ship management business, instead looking for partners in whom they can entrust many of the day-to-day operational details, leveraging the 3rd-party expertise while reducing their own overhead. Read more about life onboard these tankers as they deliver products coast to coast in the Crowley Connections article Anchors Aweigh. The Challenge The bankruptcy of U.S. Shipping Partners…

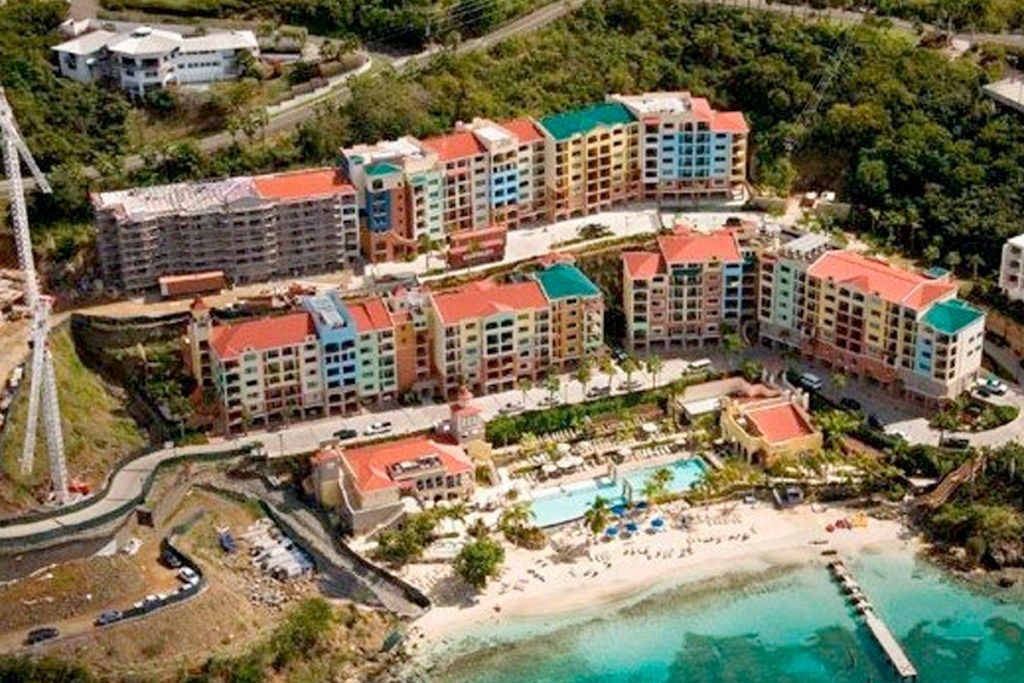

Customer Success: Frenchman’s Cove St. Thomas

More and more new resorts are popping up throughout the Caribbean. But unlike construction on the U.S. mainland, building a resort on these islands represents a logistical dance that must be choreographed months or even years in advance. After all, when you’re 1,000 nautical miles from the nearest lumberyard, running short of plywood is no small thing. With so much on the line and the margin for error so narrow, an increasing number of builders are turning to Crowley to ensure it all goes smoothly. Read more about Crowley’s ability to seamlessly handle project cargo in the Caribbean in the…

Customer Success: Global Ship Management

Global Industries constructed and launched two of the first deep-water, derrick pipe-laying vessels of their kind to install offshore platforms, build and lay deep-water pipelines, install subsea infrastructure and decommission offshore facilities worldwide. The vessels, the Global 1200 and Global 1201, delivered in 2010 and 2011 respectively, are large enough to house more than 260 people on board for months at a time. Because of their size and the type of work they do, the vessels are equipped with electric motors and propulsion, as well as satellite-based Dynamic Positioning 2 (DP2) for precise maneuvering. Read more about Crowley’s global ship…

Customer Success: Parker Drilling AADU Sealift

Crowley’s Solutions group was hired by Parker and BP to move two Arctic Alaskan Drilling Units (AADU), collectively weighing more than 10,000 tons, from Vancouver, Wash., to Prudhoe Bay, a trip of more than 3,000 miles. Both modules were loaded onto the heavy-strength deck barge, 455-5, for tow from the Columbia River to the North Slope by the high-torque Crowley tugboat Guardsman. At Prudhoe Bay, each of the six self-propelled modules were hauled one at a time onto the 455-4 (a process called “lightering”) and was then pushed through six-foot deep water by Crowley’s shallow draft tugs to shore. Read…

Customer Success: Crowley Transports Massive 98,000-Pound Electrical Equipment Enclosures

In March of 2015, Crowley’s liner services group transported two massive electrical equipment enclosures with a combined weight of 196,000 pounds to San Juan, Puerto Rico This was a feat that required shifting the company’s 580-foot triple-deck barge La Princesa beside its normal berth at the Crowley terminal in Jacksonville, Fla., so that the pieces could be rolled onto the lower deck of the barge free of obstruction from the loading ramp. Read more about Crowley’s supply chain solutions for breakbulk, NIT and project cargo shipping. The Challenge Crowley was contracted by ATS International (ATSI) for the ocean transportation of the 12-foot…

Customer Success: Installing Customer Furie’s Kitchen Lights Natural Gas Production Platform

In late summer 2015, Crowley’s marine solutions team completed the successful installation of customer Furie’s Kitchen Lights natural gas production platform and underwater pipeline in Cook Inlet, Alaska. The project, which spanned two years from the planning phase through completion, was the most recent project in which Crowley served as the prime contractor. It resulted in an incredible amount of engineering and preparation; nearly 300 on-site, contracted workers; up to 20 support vessels, both Crowley-owned and chartered; and loads of innovative thinking. Read more about Crowley’s total solution for Furie during this project in the Crowley Connections article Crowley Shines during…

Customer Success: Delivery of Offshore Oil Production and Drilling Platform, Olympus

Four of Crowley Maritime Corp.’s ocean class tugboats, Ocean Wind, Ocean Wave, Ocean Sky and Ocean Sun, completed the successful delivery of the offshore oil production and drilling platform, Olympus, to the U.S. Gulf of Mexico. The project was significant because it provided the first opportunity for all four of the company’s high-bollard-pull, ocean class tugboats to work together on any single job. The rig, owned by Royal Dutch Shell, is also considered the largest tension-leg platform ever to be developed for the U.S. Gulf of Mexico. Read more about these high-bollard pull tugs in the Crowley Connections article Power…