Tugdock, Crowley Partner to Innovate Solutions for Floating Offshore Wind Energy

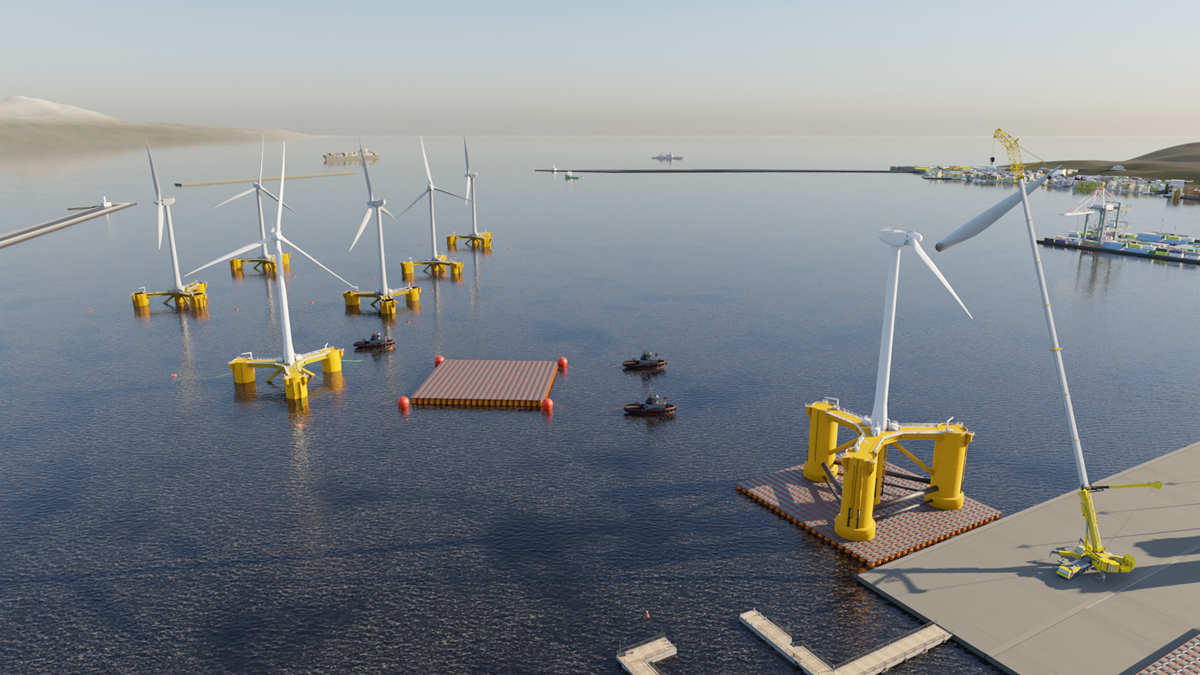

Crowley announced today a new investment in Tugdock, developers of the world’s first road-transportable floating dry dock known as the Tugdock Submersible Platform (TSP), to help advance offshore wind energy in the U.S.

Crowley, a U.S.-based supply chain solutions company serving the offshore wind sector, and Tugdock will explore potential use of the platforms in locations, such as the U.S. West Coast, where depth and conventional dry docks may be ill-suited for the logistics required.

“This important investment and collaboration with Tugdock strategically complement our vision and market-leading logistics capabilities to support wind energy development from beginning to end,” said Bob Karl, senior vice president and general manager, Crowley Wind Services. “Not only will we help installation developers solve logistics challenges, as a leader in sustainable and innovative maritime logistics Crowley will further the use of offshore wind as a leading alternative energy source by working together with our customers, suppliers, policymakers and others across our value chain for innovations like the Tugdock Submersible Platform.”

In September 2022, the U.S. government announced a goal to deploy 15 gigawatts of installed floating offshore wind capacity off the coast by 2035—enough clean energy to power over 5 million American homes. This supports a U.S. target to reduce the cost of floating offshore wind energy by more than 70-percent, to $45 per megawatt-hour by 2035.

Crowley Wind Services is developing and planning wind terminals in California, Louisiana and Massachusetts. At the California Port of Humboldt Bay, Crowley is progressing on an agreement to build and operate a terminal for manufacturing, installation and operation of offshore wind floating platforms, use of large heavy cargo vessels and provide crewing and marshalling services for the Pacific waters recently approved for leases for wind energy. Humboldt and other West Coast installations will rely upon floating offshore wind turbines.

“We are delighted to form a new partnership with Crowley, a visionary company at the forefront of marine innovation,” said Shane Carr, CEO of Tugdock, which is based in Cornwall, UK.“Their strategic investment will enable us to take our unique technology to the U.S. floating offshore wind market for the first time. We believe that our new partnership will help accelerate the growth of floating offshore wind in the U.S.”

Tugdock recently participated in Crowley’s first Innovation Expo in Jacksonville, Fla., where start-up ventures pitched their innovations for the advanced energy, sustainability, supply chain and technology sectors.

Tugdock’s award-winning, patented TSP technology offers a cost-effective solution for developers and ports in the floating offshore wind industry. TSPs were developed to be launched in ports that lack the sufficient water depth and assembly space required to build and loadout the massive floating substructures required to support offshore wind turbines. The technology allows floating dry docks to be delivered by road in modular form and assembled at the port to dimensions far wider than most of the world’s existing dry docks. Once loaded, the platform is then towed to deeper water for launching and transporting the turbines.

“The cost and time constraints associated with port infrastructure developments and submersible barge suitability are major bottlenecks holding back growth of the floating offshore wind sector,” said Lucas Lowe-Houghton, director of strategy and growth at Tugdock “Our TSP technology helps overcome these issues, providing a ready-to-go solution that does not require planning or environmental permissions. This is a massive benefit as planning permission for a permanent facility could significantly delay project schedules and not provide a return on investment. Tugdock provides a purpose-built permanent or temporary pre-assembly solution for construction and loadout, wind turbine generator integrations and major repair campaigns.”