Harnessing Offshore Wind Energy

The winds of change are here.

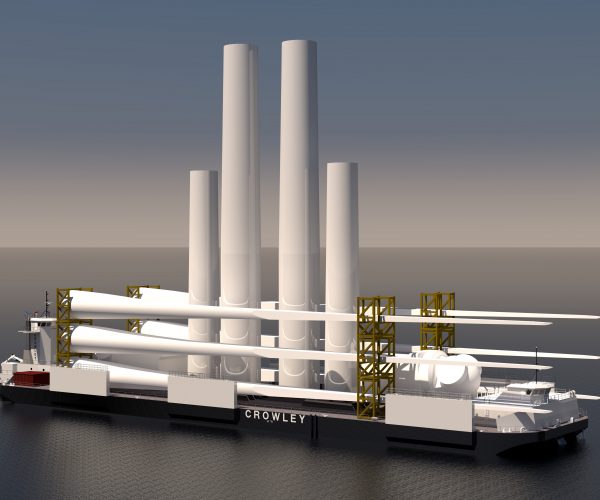

Crowley is ready for the offshore wind power surge.

The Bureau of Ocean Energy Management projects that by 2030 there will be 2,000 wind turbines off the Atlantic coast, but America has a ways to go before it has all those blades spinning. As of December 2019, the East Coast only had five offshore wind turbines in operation.

Experts believe it’s just the calm before the storm. Nevertheless, making the shift to clean, plentiful offshore wind power will come with serious challenges. Overcoming them will take American innovation and determination on a scale rarely seen in our country’s history.

Crowley is committed and energized to help provide the solutions to the challenges wind power companies will face at every stage of their growth and ongoing operations.

“Offshore wind power is the next big market in the U.S. and the next big offshore market,” Bruce Harland, vice president, wind farm program, Crowley offshore services states. “I think in the next five years, it’s going to overtake oil and gas in terms of revenue generation and opportunity.”

Enormous Opportunities in Offshore Wind Bring Enormous Challenges

Today’s key challenge impeding widescale wind farm implementation is that the U.S. lacks an established infrastructure or supply chain for the endeavor.

“In Europe, they started this 20 years ago and built a supply chain network over time,” Harland explains. “The expectation on the part of the developers is that that supply chain is instantly available to them in the United States as well—and that’s where they’re struggling because we have no offshore wind infrastructure or supply chain developed yet.”

Simply imitating European processes and importing their talent and assets won’t work, either. The Jones Act requires companies doing business in American waters to use American-built, American-flagged, American-operated vessels.

Crowley is one of the few organizations that can quickly and seamlessly develop that supply chain and provide developers, installers and companies entering the market with everything they need. Crowley has the largest fleet of Jones Act-compliant tugs and barges and unparalleled personnel resources for standing up American crews and ship management teams.

Projects This Size Benefit From One-Source Solutions

Wind power companies entering the U.S. market have big needs—infrastructure and supply chain just for starters. Because of the newness of the American market, it’s hard for companies to know what they don’t know or will need.

Facing this uncertainty, Crowley provides a turnkey supply chain solution for piecing these massive projects together. Crowley, its subsidiaries and partners can provide assets and services for every phase and any need spanning from design and transportation to ongoing operations and maintenance. No project is literally too big. Crowley’s 125-plus year maritime history includes some of the world’s largest sealifts and successful operations in the most isolated and austere environments on earth.

By being one source of accountability and one point of contact, Crowley brings inherent efficiencies that save time, control costs and reduce miscommunication and its risks. “With Crowley, companies benefit from having a single-source provider for U.S. feeder supply chain services,” explains Jeff Andreini, director, business development of Crowley offshore services.

Crossover Skills in Oil and Gas Are a Natural

As a result of decades of experience in the offshore oil and gas industry, Crowley brings the know-how that wind power producers need. According to Cole Van Gundy, director sales and marketing of Crowley offshore engineering services, “We can analyze the weather, we know how the equipment operates and we have the necessary safety systems in place. By managing more of the offshore project, we can reduce the overall program risk.”

Offshore oil and gas project requirements are similar to those of offshore wind power projects in many ways. Crowley brings heavy lift expertise and longstanding relationships with the heavy lift operators as well as marine warranty surveyors.

Two other things Crowley brings to largescale wind power projects are the redundancy of equipment from its unrivaled fleet serving the petroleum market and its deep bench of in-house expertise from years of project management in the field.

With offshore wind power, Crowley is reprising its supporting role in other emerging energy markets where it also surmounted offshore challenges. Andreini observes, “I think it’s truly exciting that we are doing the same thing Crowley did some 50 years ago when it helped the oil and gas industry get started up in Alaska through multiple sea lifts. Now it’s almost like we’re doing the same thing in a new evolution of energy for offshore wind.”

Marine Engineering Expertise Is Integral to Success

Hundreds of new vessels for installation, supply and transfer are needed to meet industry projections and ensure project certainty. Building them will require Americanization of European designs in order to meet Jones Act requirements and U.S. regulations. Through Crowley’s marine engineering arm, Jensen, Crowley provides customers with a seamless, in-house solution that ensures compliance while incorporating Crowley’s deep knowledge base from operating one of the world’s most diverse fleets.

In Americanizing vessels, companies face unique challenges. For example, engineers must avoid spec’ing European plate sizing and framing that are not readily available in the U.S. In addition, designs must meet tonnage requirements that are unique to the U.S. Crowley experts know how to adapt European designs for contingencies like these while minimizing costs and maximizing performance.

Americanize Through Vessel Sourcing and Construction Management

Experienced, hands-on construction management is essential when it comes to building specialized vessels to support wind farm installations and operations.

Crowley has been building in the U.S. with all of the major shipyards for over 15 years and has managed more tonnage than any other Jones Act provider or U.S. ship owner. That experience gives Crowley insider knowledge and understanding of shipyards. According to Van Gundy, “Knowing their preferences, tendencies, strengths and weaknesses guides the way we manage construction with the right people and processes to ensure that we get the best product out of the yard at a competitive price.”

Plan for Success Throughout the Lifecycle

Crowley takes the one-source concept to the next level as a one lifecycle provider. Once a wind farm is installed, wind power companies can turn to Crowley for operations and maintenance as well as help managing the terminal and vessel activity.

Crowley’s experience servicing offshore oil and gas drilling installations, largescale logistics projects and even ongoing fueling operations makes them a proven long-term partner well suited for supporting ongoing wind power operations. Leveraging its integrated divisions, dedicated assets and project familiarity, Crowley’s offshore services stretch throughout the 20- to 25-year project lifecycle for wind farms. That role extends to making needed repairs and upgrades. It includes crewing and ship management. And it ends with decommissioning.

Go All-In for Wind with A Partner Who’s Already There

The winds of change won’t stop. The only unknown at this point is how they will start.

The start won’t be easy with the need for a new generation of vessels and the current lack of an established supply chain and infrastructure.

Crowley, with its legacy of success on challenging maritime endeavors, ready assets and established expertise in offshore oil and gas is the ideal partner to support a strong start, a bountiful wind harvest and a profitable lifecycle.

Learn more about Crowley’s offshore wind services, or meet with the team to shoot the breeze about your project.